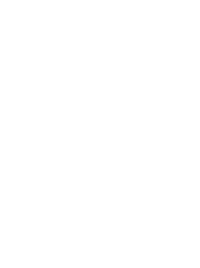

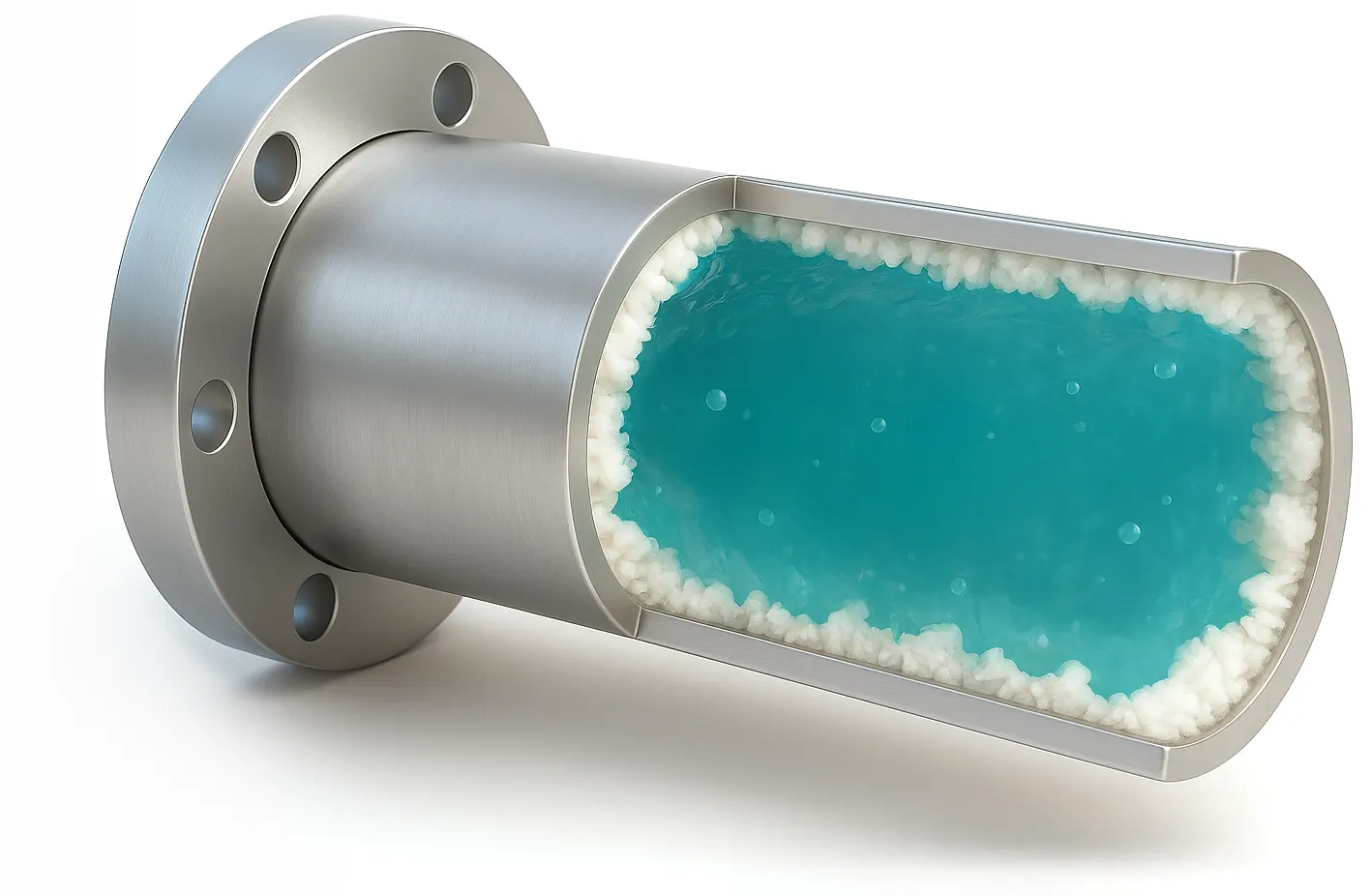

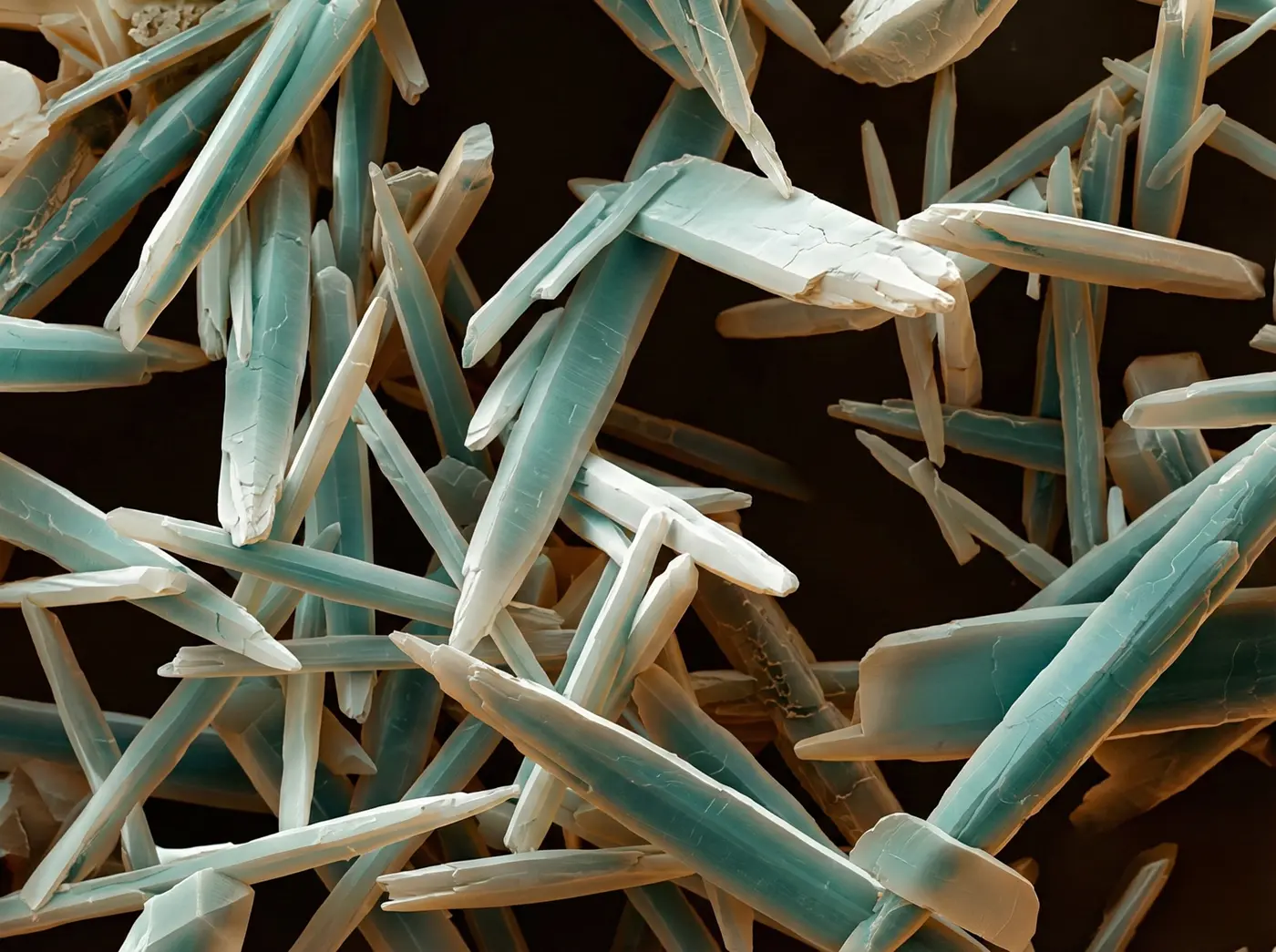

The catalytic alloy core changes the structure of hardness minerals, forming soft crystals that stay suspended instead of bonding to pipework or heat-transfer surfaces.

Magcat

Industrial & commercial scale prevention system

FOR POINT-OF-ENTRY

When scale threatens performance, prevention pays for itself

Protect boilers, chillers, and process systems from limescale and corrosion — without chemicals, power, or maintenance. Designed for the most demanding industrial and commercial applications, Magcat delivers long-term, chemical-free protection that keeps your systems efficient, reliable, and compliant.

FOR POINT-OF-ENTRY

WRAS Approved

Reg 4 compliant

UK manufacturer

GSA verified

10-year warranty

50 years of R&D

The real cost of scale

How Magcat works

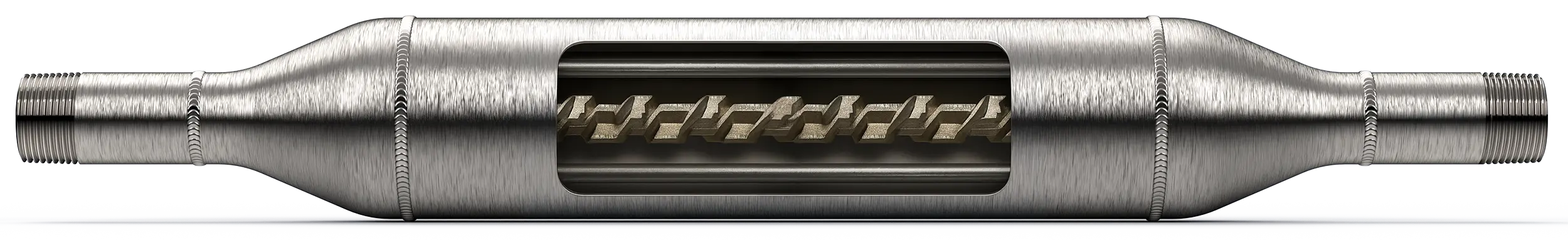

As water flows through Magcat, its dual-treatment technology delivers magnetic and catalytic scale prevention in one integrated process.

Catalytic transformation

Magnetic stabilisation

A surrounding magnetic array stabilises these crystals, strengthening the treatment effect even under extreme or variable water conditions.

Scale control & system protection

Together, these processes prevent new scale, gradually reduce existing deposits, and maintain consistent energy performance across potable, processed, recycled, and wastewater streams.

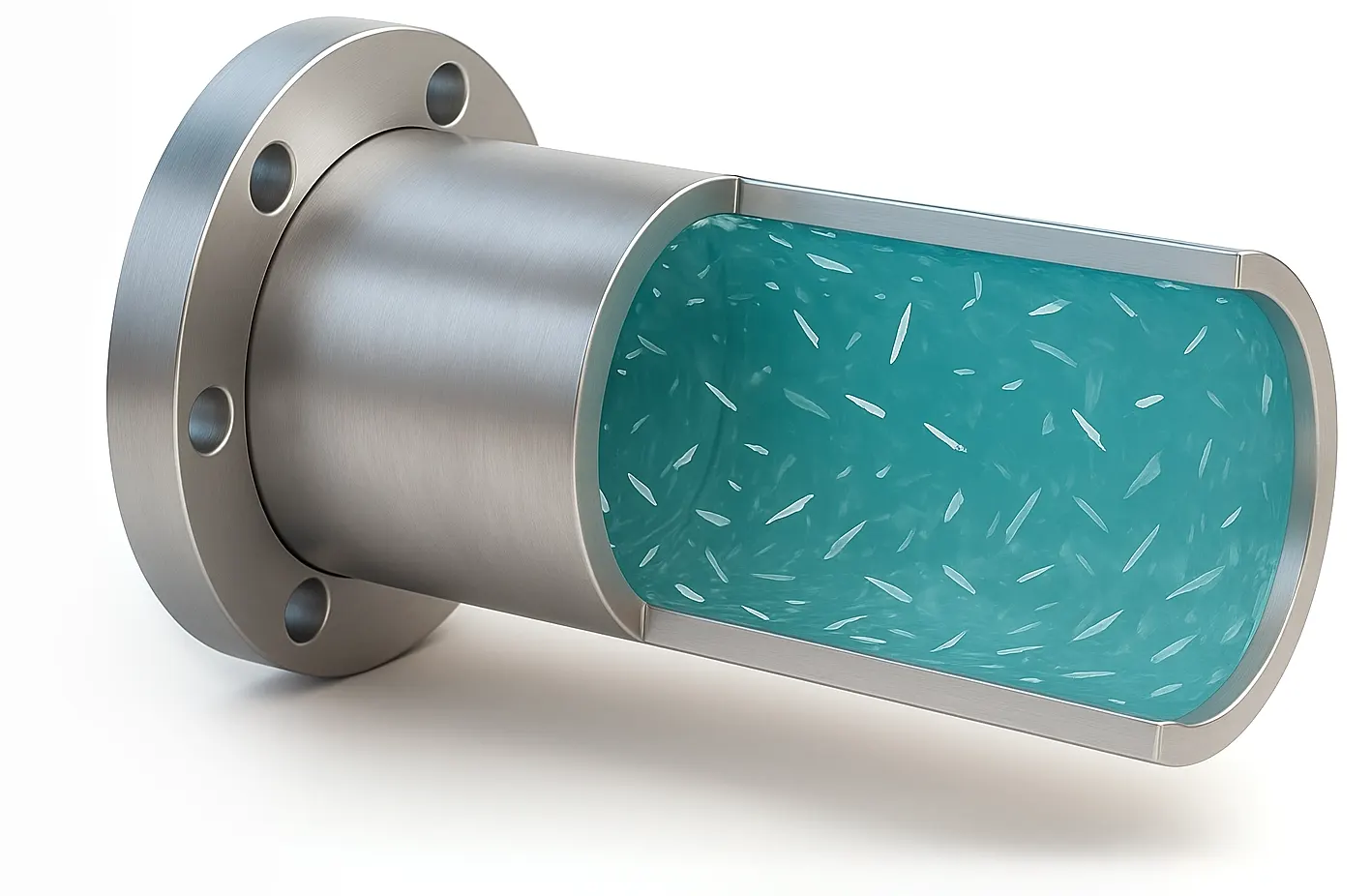

Untreated water

Scale forms as crystals that stick to surfaces and build up as hard deposits

Treated water

Scale forms as crystals that flow freely and do not attach to surfaces

Technical advantages

CARBON-SAVING SOLUTION

Cleaner heat exchangers and boilers improve energy efficiency

GREEN TECHNOLOGY

No chemicals, dosing, consumables or discharge and 100% recyclable

STOPS SCALE FORMATION

Prevents limescale deposition inside pipes and equipment

REDUCES CORROSION

Protects infrastructure and extends asset life

NO MAINTENANCE & LONG-LIFE

Once installed, units operate for decades

PROVEN TECHNOLOGY

Trusted globally in industrial, commercial, and residential systems

Proven performance by application

Manufacturing / Industrial cooling – Thai Honda

Pressure loss reduced from 68% → 45%. Pump power use cut by 6.6%. Existing scale removed; efficiency restored.

Oil & gas / Offshore compression – ONGC

Cleaning interval extended from 65 → 163.5 hours and 172 → 367 hours. Downtime and chemical use significantly reduced.

Pharmaceutical / Healthcare – Pfizer UK

Annual savings of £13,000 in labour and chemical costs. ROI achieved within six months.

Each installation confirms what decades of testing have proven — Magcat delivers measurable, lasting results even in the harshest environments.

Compare the difference

| Treatment type | Capex cost | Opex cost | Servicing requirement | Downtime risk | Environment impact | Lifespan |

|---|---|---|---|---|---|---|

| Magcat | Moderate | None | None | None | None - 100% recyclable at end of life | Up to 20 years |

| Chemical dosing | Low | High | Regular + handling | Yes | Chemical discharge + plastics | Consumed immediately |

| Water softener | High | Moderate | Salt refills and annual servicing | Yes | Chloride discharge + plastics | 10 years |

| Descaling | None | High | Regular cleans | Yes | Energy waste | None - equipment lifespan compromised |

ROI & sustainability impact

Magcat pays for itself through energy savings, reduced maintenance, and longer system life.

Magcat applications

Commercial buildings

Leisure facilities

Hotels

Industrial processing

Healthcare

Property development

Manufacturing

Food & beverage

Schools & universities

Agriculture

HVAC & cooling towers

Maritime

Independent validation

With a service life exceeding 25 years and thousands of installations worldwide, Magcat is the proven choice for non-chemical water softening. Our technology is backed by over 50 years of research and explicitly verified by the US GSA, with additional scientific validation from the University of Reading and Brunel University. Whether for potable or process water, Magcat offers a reliable, scientifically confirmed solution.

British engineering & manufacture

Magcat is designed and manufactured in the UK to meet the highest standards of performance and durability. Each unit is built from marine-grade stainless steel and WRAS-approved catalytic alloy components, engineered specifically for industrial and commercial water conditions.

Production, testing and quality assurance are all handled domestically, ensuring traceability and consistency from end to end. Every Magcat is supported by Evolve Water’s UK-based technical team and installer network and backed by a 10-year pro-rata warranty.

Technical snapshot & downloads

Treatment type: Dual (magnetic + catalytic)

Connection range: DN15–DN400 (½″–16″)

Operating pressure: Up to 16 bar

Temperature range: 0–100°C

Construction: Stainless-steel housing with catalytic galvanic alloy core

Warranty: 10 years (pro-rata)

Service life: 25+ years

Pressure drop: <2% when correctly installed

Downloads:

Frequently asked questions

How long does Magcat last?

Magcat has a minimum service life of 25 years and is supplied with a 10-year pro-rata warranty. Many units have operated in the field for decades without replacement or maintenance.

Does it remove hardness from the water?

No – Magcat doesn’t remove calcium or magnesium ions but changes how they behave. The catalytic process prevents them from bonding to surfaces, keeping them suspended so scale can’t form.

Will Magcat reduce existing scale?

Yes. Over time, it gradually dissolves and loosens existing scale deposits, particularly in systems where flow is consistent and temperature is stable.

Does Magcat affect water chemistry or compliance?

No. It doesn’t add or remove any substances, alter pH, or change mineral content, so it maintains full WRAS and Reg 4 compliance.

Can it be used with other treatment systems?

Yes – Magcat can be installed alongside filtration, UV or softening systems if required. It’s completely passive and doesn’t interfere with other processes.

Where should it be installed?

Ideally close to the point of entry or before the plant equipment you want to protect (e.g. boilers, chillers, or heat exchangers). It can be installed horizontally or vertically.

What maintenance does it require?

None. Once installed correctly, Magcat operates continuously without power, calibration, or servicing.