RESOURCES

Privacy & terms

Quality Policy

Water heater manufacturer case study

Magcat maintained full heater efficiency for 12 months in 280 ppm hard water, with zero scale formation.

Region: United Kingdom

Application: Water heater protection in hard water area

Sector: Commercial

Product: Magcat water conditioner

A leading global water heater manufacturer was seeking a reliable conditioning solution for installations in hard water areas. Traditional conditioners had produced inconsistent results, often leading to reduced efficiency and costly maintenance within just a few months of operation.

The challenge

The solution

Results after six months

After six months of continuous operation, the efficiency of the heat exchanger was assessed using temperature readings taken directly from the water heater.

Results after 6 months: 366ppm

Results after 6 months: 280ppm

When checking for limescale within a water heater, the key comparison is between the set temperature and readings from Point 2 (outlet) and Point 11 (heat exchanger exit). When the water heater operates at 60°C or higher, all three readings should remain within ±1°C of each other.

If Point 11 is higher than Point 2, it indicates scale formation, as limescale acts as an insulator, forcing the heater to overwork in order to transfer heat, which can lead to overheating and eventual failure.

In both trials, Points 2 and 11 remained within the correct parameters, with Point 11 matching the set temperature exactly. These readings confirmed no signs of limescale formation after six months of continuous operation in either site.

Stamford site update

Correct flow sizing and a minimum ~1m pipe run before the heater are critical for catalytic performance and effective treatment. Consult the manufacturer for sizing guidance.

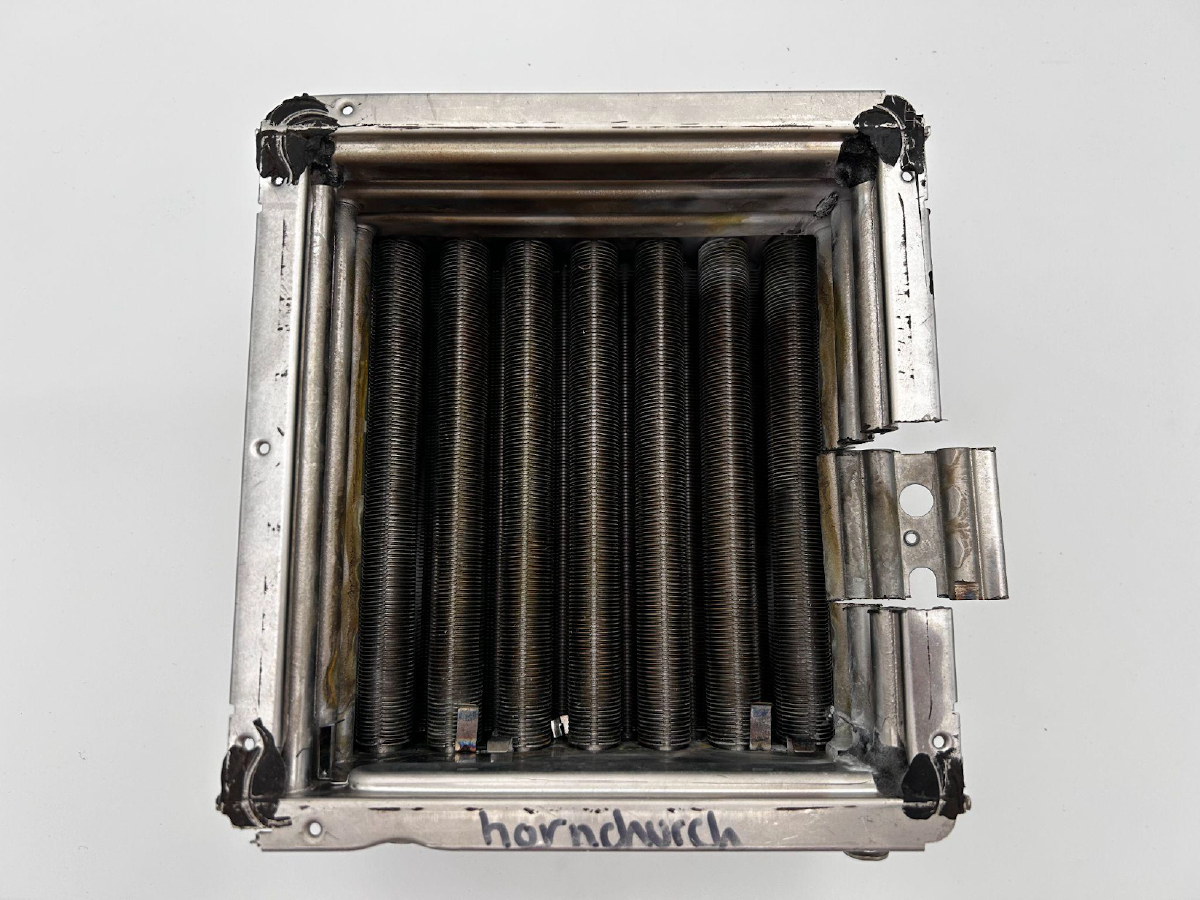

Findings after 12 months: 280ppm

The 366 ppm site will not be cut open until February 2026, as its conditioner was installed in February 2025.

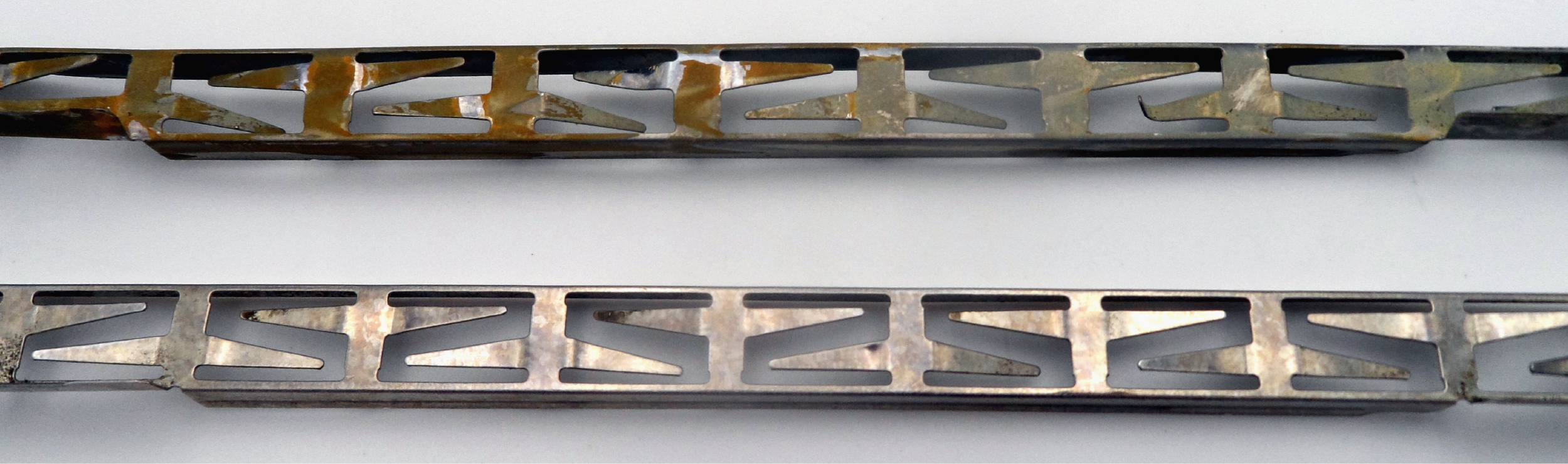

Heat exchanger after 12 months of continued use

The following data was extracted showing peak performance was maintained after 12 months.

Comparison

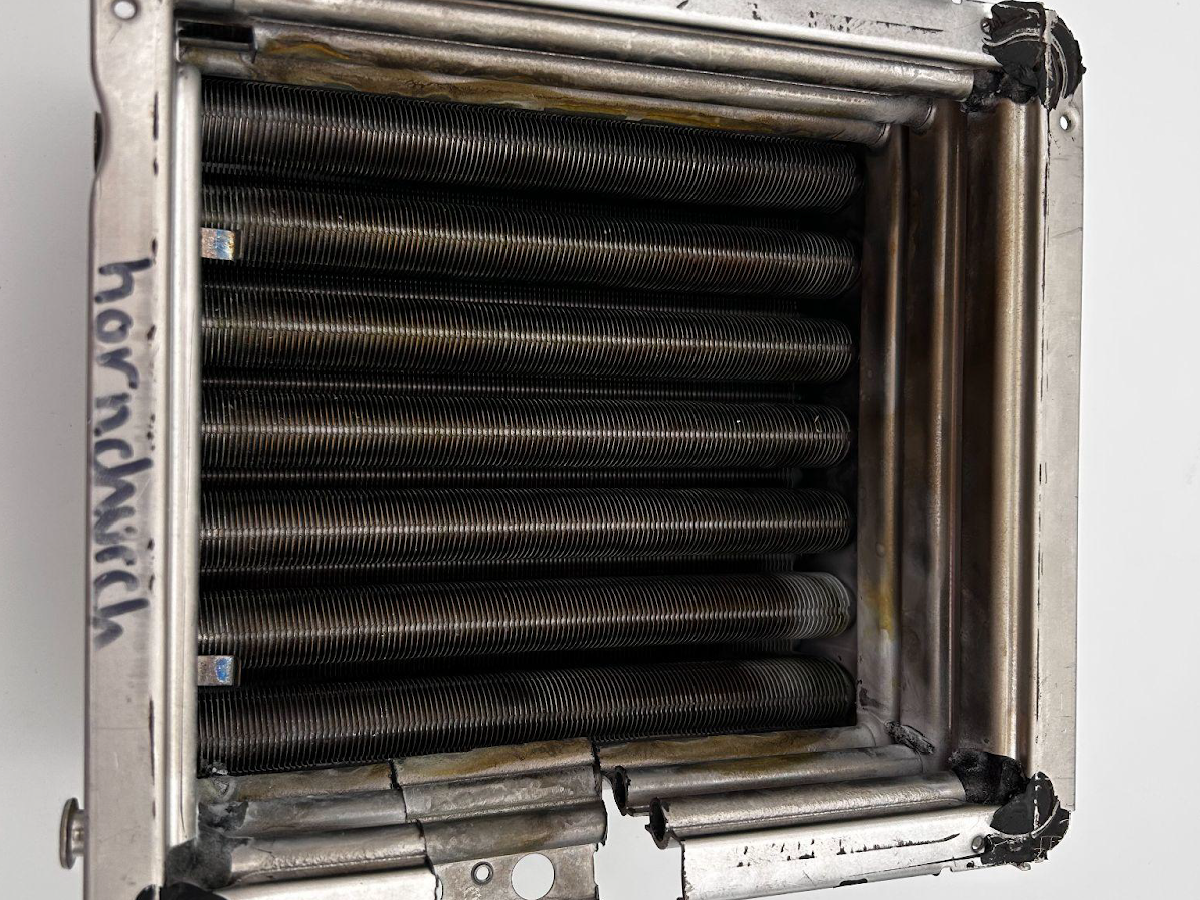

Heat exchanger after 3 months using a competitor’s conditioner

Magcat: scale-free after 12 months vs competitor: heavy scale after 3 months

Outcome

Magcat provided a maintenance-free, chemical-free solution that kept the heater operating at peak efficiency for 12 months in very hard water, outperforming alternative conditioners by a wide margin.

Related case studies