RESOURCES

Privacy & terms

Quality Policy

Daimler Truck case study

Magcat reduced scale build-up in Daimler’s test facility, cutting downtime and protecting critical cooling equipment.

Client: Daimler Truck

Region: Germany

Application: Engine testing cooling system

Sector: Automotive

Product: Magcat water conditioner

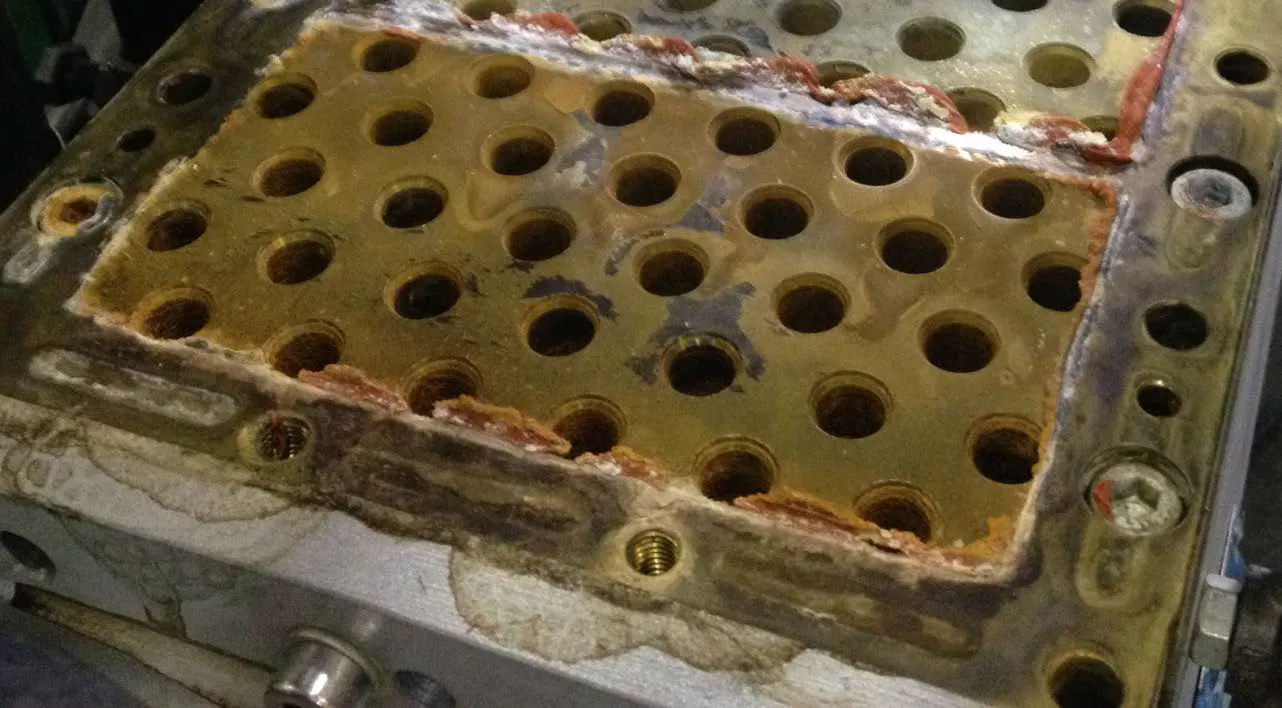

Daimler Truck operates extensive engine testing facilities, where multiple engines run continuously under controlled conditions. Cooling water is circulated through charge air coolers (CACs) and other components, with heat ultimately rejected via a cooling tower. Persistent scale formation in the system was reducing efficiency and causing frequent cleaning shutdowns.

The challenge

The solution

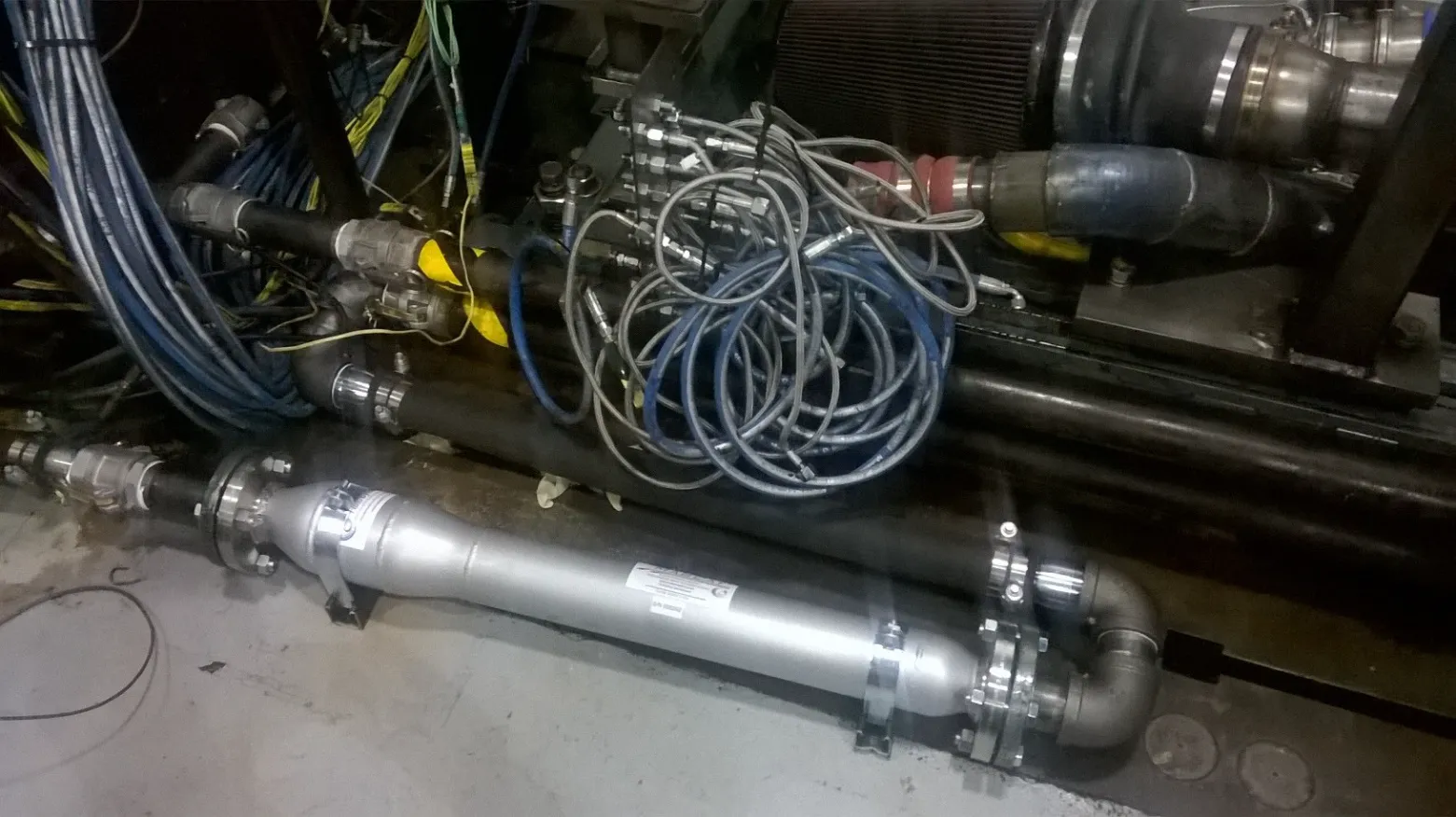

After consultation with Fluid Dynamics and review of system data, a 3” Magcat unit was specified for the WOW stand, sized to treat a design flow of 118 gallons per minute. The dual-treatment Magcat system was installed in March 2016.

Results

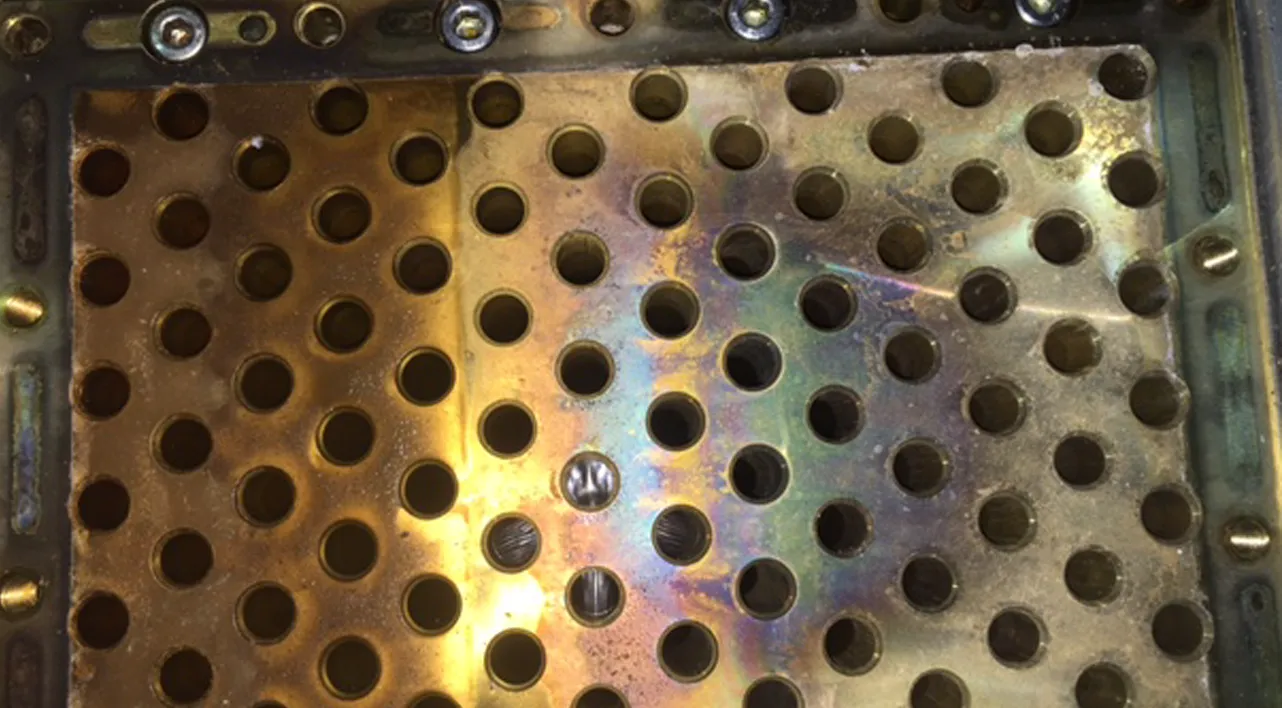

Unprotected CAC

Magcat protected CAC after 1000 hours

Related case studies