RESOURCES

Privacy & terms

Quality Policy

Honda case study

Magcat reduced scale, cut energy use, and lowered running costs for Honda’s compressor cooling system.

Client: Honda

Region: Thailand

Application: Cooling water for compressors

Sector: Manufacturing

Product: Magcat water conditioner

Honda has operated in Bangkok since 1965, producing automobiles, motorcycles, and power tools for the Asian market. At its manufacturing plant, a bank of 220 kW air compressors and dryers provides compressed air for production processes. These systems generate large amounts of heat, requiring continuous cooling with circulated water.

The challenge

The solution

A Magcat conditioner was installed on the feed line to one compressor during a six-month trial. Engineers collected baseline data before installation and monitored scale formation, pressure losses, and pump performance throughout the trial.

Results

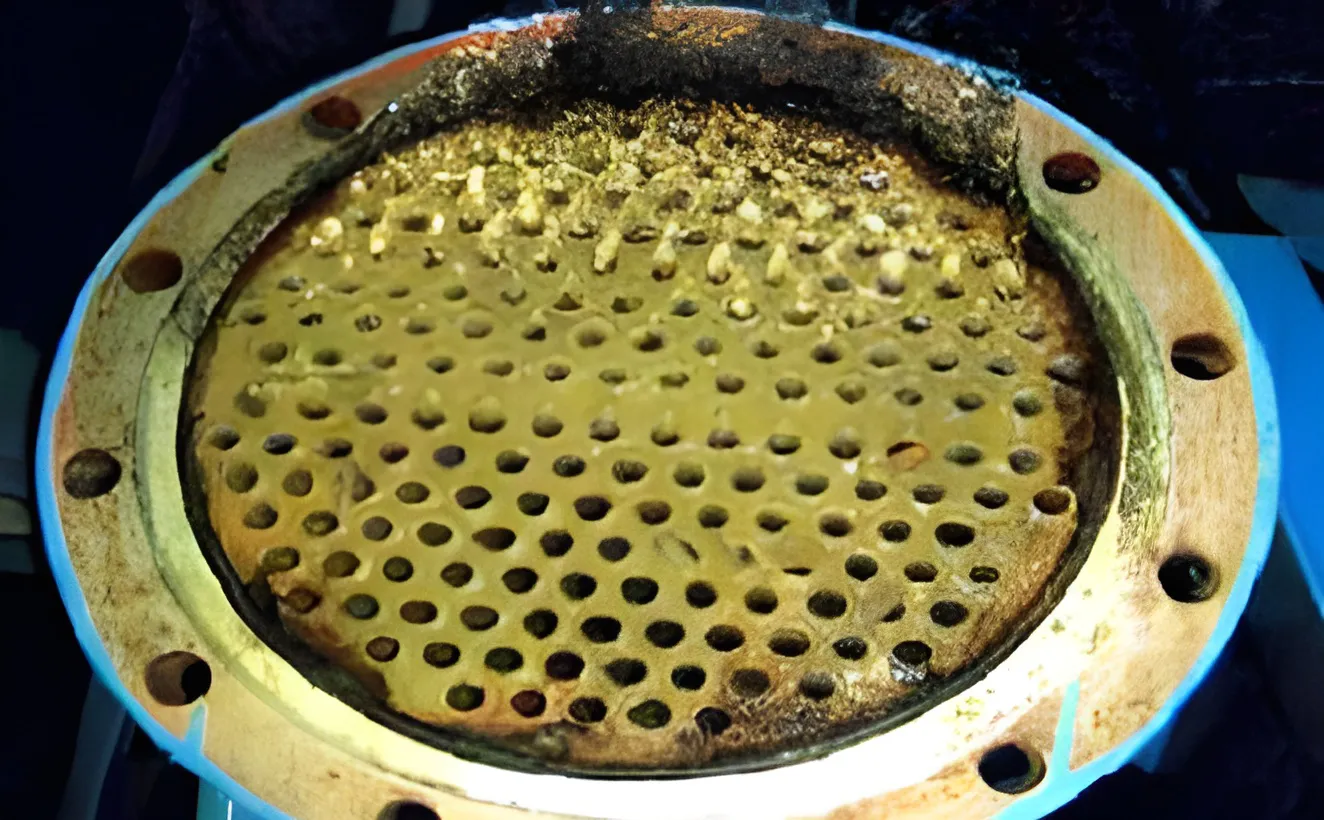

Before

After

Related case studies